How TQM principal is aligned with process quality improvement?

Module II. Process Quality Improvement

Lecture – 3 How TQM principal is aligned with process quality improvement?

Total quality management (TQM) is a strategy for implementing and managing quality improvement activities on an organization-wide basis. TQM began in early 1980s, with the philosophies of Edward Deming and Joseph Juran as the focal point. It evolved into a broader spectrum of concepts and ideas, involving participative organizations and work culture, customer focus, supplier quality improvement, integration of quality system with business goals, and many other activities to focus all elements of organization around quality and process improvement goal. Typically, organizations that have implemented TQM approach to quality improvement have quality councils or high-level teams that deal with strategic quality initiatives, workforce-level teams that focus on outline production or business activities, and cross-functional teams that address specific process quality improvement issues. TQM strongly emphasizes on variability reduction, the prime theme of process quality improvement.

However, TQM has only moderate success for process improvement for a variety of reasons. Some general reasons for lack of conspicuous success of TQM include (i) lack of top down, high-level management commitment and involvement; (ii) inadequate use of statistical methods and insufficient recognition of variability reduction as a prime objective; (iii) diffuse as opposed to focused, specific objectives; and (iv) too much emphasis on widespread training as opposed to focused technical education and actual implementation.

Some of the approaches which is extended and used from TQM philosophies are:

Quality Standards

International Standards Organization (ISO) has developed a series of quality standards including ISO 9000 series. Focus of these standards is quality system, including components such as management responsibility for quality, design control, document and data control, purchasing and contract management, product identification and traceability, inspection and testing, including control of measurement and inspection equipment, process control, handling of nonconforming product, corrective and preventive actions ,handling, storage, packaging, and delivery of product, service activities, control of quality records ,internal audits, training and statistical methods.

Just-in-Time, Lean Manufacturing, Poka-Yoke, and Others

There are many initiatives devoted for improving production/manufacturing process. Some of these include Just-in-Time approach emphasizing in-process inventory reduction, reduced set-up time (SMED), and a pull-type production system; Poka-Yoke or mistake-proofing in the processes; Toyota production system (TPS), reengineering; theory of constraints (TOC); agile manufacturing; lean manufacturing; and so on.

Customer Focus

Most important asset of any organization is its customers. An organization's success depends on how many customers it has, how much they buy, and how often they buy. Satisfied customers buy more and more frequently. They also pay their bills promptly, which greatly improves cash flow of an organization.

Increasingly, manufacturing and service organizations are using customer satisfaction as a measure of quality. This fact is reflected in Malcolm Baldrige National Quality Award, where customer satisfaction accounts for 30 percent of the total points. Similarly, customer satisfaction standards are woven throughout the ISO 9000: 2008 standard. Customer satisfaction is one of the major focuses of a effective quality management system.

Who are the Customers?

There are two distinct types of customers-external and internal. An external customer is the one who uses the end product or service or one who purchases product or service. Whereas, internal customer are always defined within the organization/interlinked processes (e.g. marketing department may be an internal customer for production department).

Customer Perception of Quality

One of the basic concepts of TQM philosophy is continual improvement. This concept implies that there is no acceptable quality level because the customer's needs, values, and expectations are constantly changing.

Before making a major purchase, some people check consumer magazines that rate product quality. During 1980 to 1988, quality of a product and its performance ranked first, price was

second, and service was third. During 1989 to 1992, product quality remained the most important factor, but service is ranked above price in importance.

An American Society for Quality (ASQ) survey on end user perceptions for important factors that influenced purchases showed following ranking:

1. Performance

2. Features

3. Service

4. Warranty

5. Price

6. Reputation

The factors of performance, features, service, and warranty are part of the product or service quality; therefore, it is evident that product quality and service are more important than price. Although this information is based on retail customer, it appears, to some extent, to be true for the organizational customer also.

Translating the Customer Needs into Requirements

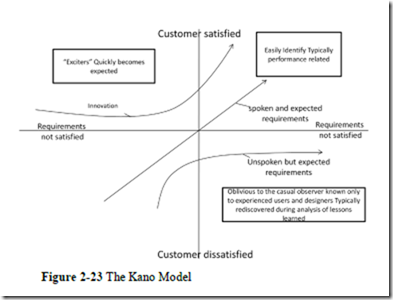

Kano model, which is shown in Figure 2-23, conceptualizes customer requirements. The model represents three major areas of customer satisfaction. The first area of customer satisfaction, represented by diagonal line, represents explicit requirements. These include written or verbal requirements and are easily identified, expected to be met, and typically performance related. Satisfying customer would be relatively simple if these were the only requirements.

The second area of customer satisfaction represents innovations, as shown by curved line in the upper left corner of the figure. A customer's written instructions are often purposefully vague to avoid stifling new ideas during conceptualization and product definition. Because they are unexpected, these creative ideas often excite and delight the customer. These ideas quickly become expected w.r.t time.

The third and most significant area of customer satisfaction represents unstated or unspoken requirements, as shown by the curve in the lower right corner of the Figure.

The customer may indeed be unaware of these requirements, or they may assume that such requirements will be automatically supplied. Basic specifications often fail to take real-world manufacturing requirements into account; many merely are based on industry standards or past practice. These implied requirements are most difficult to define but prove very costly if ignored. They may be rediscovered during an after-the- fact analysis of lessons learned.

Realistically customer doesn’t buy a specification; customers buy a product or service to fulfill his need. Peter Drucker once said, “Customers don’t buy products, they buy results”. Just meeting a customer’s needs is not enough; organization must exceed customer’s needs. Questioners are designed to identify basic, expected and exiting features according to Kano’s Model and then translated into engineering requirement by using QFD.

Comments

Post a Comment